Category:Water Monitoring

Model:UV600TPTN

Overview:The UV600TPTN is an on-line water analyser to simultaneously measure total phosphorus and total nitrogen based on a wet-chemical oxidation in a compliance with EN ISO 6878 and Standard Methods 4500-P, 4500-N and 4500-NO3. It belongs to a family of analyser for total parameters: TP (total Phosphorus), TN (Total Nitrogen) and TOC (Total Organic Carbon).

UV600TPTN provides a simple and fast way to measure total phophorus and total nitrogen for surface water or industrial/municipal waste water treatment plants with accuracy, stability and low operating cost.

A digestion set up enables to oxidize both organic and inorganic phosphorus and nitrogen compounds into orthophosphates and nitrates, respectively, using potassium persulfate under alkaline conditions at 95℃ and UV light irradiation. Total amount of orthophosphates is then quantified by a colorimetric module while total amount of nitrates is determined by direct UV absorbance measurement.

Phosphorus compounds such as trimethyl phosphate or polyphosphate (sodium hexametaphosphate) can be recovered up to 98% yield.

External probes can be added for physicochemical parameters like pH, ORP,dissolved oxygen, conductivity and total suspended solids.

Thanks to its automatic cleaning system, the maintenance is roughly limited to the periodic refill of the inexpensive cleaning solution and reagents.

Measurement Principle - Wet-Chemical Oxidation Followed by Colorimetry

The water sample is mixed with an alkaline decomposition solution made of potassium peroxodisulfate. The solution is heated at 95℃ and irradiated with UV light. Phosphorous compounds are converted to orthophosphates while nitrogen-based compounds are transformed to nitrates. Two different methods are used to quantify orthophosphates and nitrates.

Nitrates are quantified by direct UV absorbance at 220nm. The absorption is proportional to their concentration, based on the Beer-Lambert law.

Orthophosphates are quantified by two colorimetric methods, depending on the concentration ranges: the molybdenum blue and the vanadomolybdophosphoric methods.

In the molybdenum blue method (EN ISO 6878 and Standard Methods 4500-P), the orthophosphate ions react with ammonium molybdate and potassium antimonyl tartate under acidic conditions to afford phosphomolybdic acid. This acid is then reduced by ascorbic acid to give a colored molybdenum blue, which intensity is measured by a LED at 630nm.

In the vanadomolybdophosphoric method (Standard Method 4500-P), orthophosphates ract with ammonium molybdate under acidic conditions to afford molydbophosphoric acid. The molybdophosphoric acid reacts with ammonium monovanadate to give vanadomolybdophosphoric acid. This acid is yellow. The absorption of the solution is measured by a blue LED. In this method, the reagent has a longer lifetime than the reagents of the molybdenum blue method.

In both methods, the absorption is proportional to the phosphate concentration, based on the Beer-Lambert law. The colorimetric module has been specially developed to reach a very small volume flow cell that reduces the quantity of reagent to preserve the environment and to reduce the operating cost. The multi-wavelength LED source assumes a color and turbidity compensation with an unlimited life time.

The overall measurement typically takes 14 minutes. It can be extended tup to 20 minutes for more complex samples (longer digestion time needed). The oxidation yield was tested on different phosphorus compounds such as trimethyl phosphate and sodium hexametaphosphate (polyphosphate).

Patented Flow Cell

The patented flow cell allows to analyse very high level of suspended solids without clogging, making it suitable for industrial and municipal waste water applications. The wetted parts of the flow cell make it also suitable for most corrosive samples. The design with two cylinders enables the water to go around them, avoiding suspended particles to agglomerate and interfere with the optical measurements. The turbidity is automatically compensated by a dual-wavelength method.

Autocleaning

The analyser is designed to automatically clean itself with an adjustable time range, typically 24 hours, using sulfuric acid 5%. This autocleaning with sulfuric acid 5% proves to be more efficient than water or air autocleaning for dirty and oily samples. It prevents any clogging in the hydraulic circuit from heavily charged water samples. This autocleaning design enables uninterrupted measurements and low maintenance.

Autozeroing

Sulfuric acid has no absorbance in the UV-visible, amking ti an ideal component to measure the zero. At the end of each autocleaning cycle, the zero is performed on the sulfuric acid 5%. This frequency of zeroing is the key for successful measurements as it prevents any drift in the zero to occur.

User-Friendly Interface

The large colour touch screen (10.4") and intuitive interface available in 9 different languages (Chinese, English, French, German, Hungarain, Italian, Portuguese, Spanish, Turkish) makes very easy to test or configure the analyser.

Many test functions allow to test and troubleshoot each element of the analysers (light signal, pump, solenoid valves, etc.) to set up quickly a maintenance diagnostic.

An acid resistant protection film on the screen assumes an efficient long-term protection

Communication

The RS232 port supports the MODBUS protocol to transmit each measuring channel value to a SCADA system.

Additional parameters are available like status code, error code, calibration values band pumps run time.

Basic 4-20mA output modules can be plugged on the main board for each measuring channel, in the limit of 12 modules. A USB port enables to download on any USB key the last 5000 recorded measurements as well as a diagnostic file containing the configuration and userful information for remote trouble shooting.

The recorded measurements file can be imported to Excel for graphs or other treatments. The software of the analyser can be upgraded by connecting a USB key.

Sampling System

UV600TPTN can adapt to many different kinds of sampling depending on the application: surface water, drinking water, process water or wastewater.

A built-in peristaltic pump, synchromised with the measurement, the sample can be admitted directly inside the analyser with a maximal pressure of 4 bars. Otherwise an optional built-in peristalitc pump, synchronised with the measurement to extend the tubing life time, allows to take the sample directly from a tank located up to 6 meters below the analyser. For demanding applications with long distances, another peristaltic pump in a separate enclosure is proposed as an option.

For some applications on river water or wastewater where two sampling pummps are necessary, UV600TPTN delivers a relay contact to synchronise the primary pump. The delay and running time of each pump can be adjusted easily in the parameters menu of the analyser.

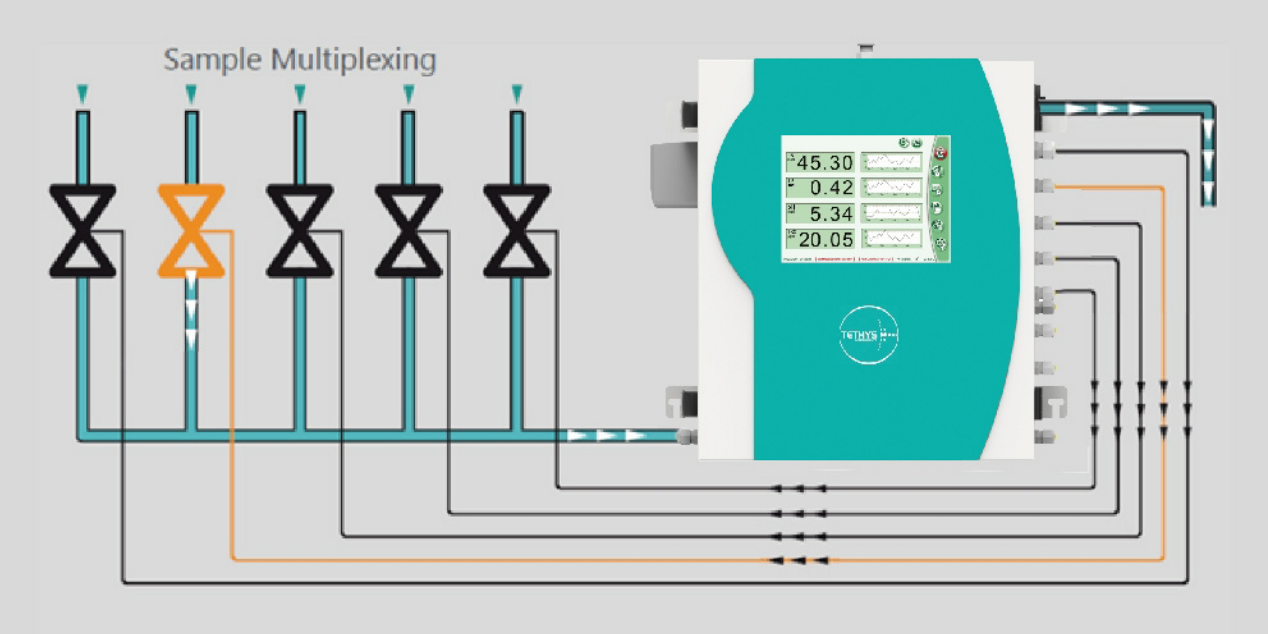

Multiplexing System

When different streams need to be analysed, an optional multiplexing system delivers relay contacts to control external electric-valves or external pumps.

Up to 6 different streams can be selected.

The measuring channels can be either duplicated (each one having its own 4-20mA output or MODBUS register) or measured sequentially to fit with the maximum of 16 measuring channels (a MODBUS register tells which stream is currently being measured)

| Parameter | Standard Range | Typical Repeatability | Accuracy |

|---|---|---|---|

| Total Phosphorus | 0-2mg/L | ±0.02mg/L | ±2% |

| 0-20mg/L | ±0.2mg/L | ||

| Total Nitrogen | 0-50mg/L | ±0.1mg/L | ±2% |

| pH | 0-14 | ±0.01pH | ±2% |

| ORP | ±2000mV | ±1mV | ±2% |

| Dissolved Oxygen | 0-25mg/L O2 | ±0.1mg/L O2 | ±2% |

| Conductivity | 0-2000uS | ±1uS | ±2% |

| Total Suspended Solids | 0-1500mg/L TSS | ±1% of reading or ±2%mg/L TSS | ±2% |

| 0-30000mg/L TSS | ±1% of reading or ±2%mg/L TSS | ±2% |

| Sample Flow | 0.6L/min (only during sampling time) |

| Sample Pressure | 0-1 bar with sampling peristaltic pump |

| Sample Temperature | 0-80℃ |

| Wet Parts Materials | Polypropylene, Polyethylene, PMMA, PEEK, FPM (Viton), Quartz |

| UV Generation | UV Lamp |

| Digestion Temperature | 95℃ |

| Measuring Time | 14-30 minutes for complex samples |

| Measurement Interval | 15 min to 720 min (if measuring time compatible) Physicochemical parameters may be continuous |

| Memory | 5000 lines of measurements (up to 16 channels) with date and time |

| Consumption | Cleaning solution (sulfuric acid 5%): 220mL/day |

| Digestion reagents per measurement: 11.3mL up to XXmL for TN | |

| Colorimetric reagent per measurement: 1.2mL | |

| Maintenance Interval | Recommended: 6 months to 1 year ( except for refilling) |

| Power Supply | 90-264V/ Maxi 500VA/50-60Hz |

| Screen | 10.4" Color TFT LCD 640*480 pixels with LED backlight |

| Communication | RS232 with MODBUS protocol, RS485 for external probes, USB |

| Certifications | CE, EN 61010-1, EN 61326 |

| Enclosure | Stainless steel with epoxy coating, IP65, wall mounting brackets |

| Ambient Temperature | -20℃ to 60℃ |

| Dimensions | 715x450x242mm (HxLxD) |

| Weight | 25kg |